welcome to Pelican

Pelican has been in the field of Onsite Machining for more than 30 years, and that makes us the first company in India to introduce the concept of Onsite machining. We sell portable machine-tools as well as provide services of On-site Machining, using our very own machines and a team of skilled technicians.

READ MORE

Onsite Machining

Onsite machining, also known as Insitu machining, is performing machining operations on any location with the use of Portable Machine-tools. Onsite machining delivers better geometrical and dimensional accuracy while saving on overall time and cost, by eliminating need for dismantling and transportation.

Boring machine

Pelican’s Portable Boring Machines are rugged and versatile machines which are primarily used for Onsite Boring and Spot Facing operations. The compact yet powerful machine can be used on Gas cut...

READ MORECircular Flange Facing Machine

Pelican’s Flange Facing Machine is a portable large diameter flange facer with a capacity to currently machine 1.5 metres to 12 metres flange diameter. The capacity can be altered to machine flanges...

READ MOREMilling Machine

Pelican has various types of portable milling machines. They all are Primarily used for machining Fabricated / Weld Built-up / Worn out / Pre-Machined surfaces and generate a flat surface. These machines are different from ...

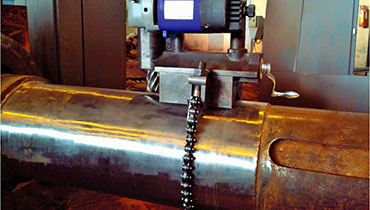

READ MOREShaft Turning Machine

Pelican’s Portable Shaft Turning Machine is used for O.D. machining of various Shafts, Pins and Trunnions. The machine is set up on the existing shaft itself and can take reference of the same shaft to maintain the ...

READ MOREKeyway Milling Machine

Pelican’s Portable Keyway Milling machine is purposefully designed and made for keyway milling operations. The machine is mainly of 2 types, External type (O.D. Mounted) and Internal type (I.D. Mounted)...

READ MOREPipe Bevelling/Pipe Cutting Machine

Pelican’s portable Pipe Bevelling / Cutting Machine is used for onsite cold cutting and bevelling of pipes. These machines are designed and manufactured for large pipe Cutting and Bevelling. The machine is mainly...

READ MOREAdvantages

Onsite machining has been proven to be a boon to various industries, be it in case of maintenance of running plant machinery or in case of new equipment manufacturing. Below are a few reasons for the popularity & use of Portable machining:-

- Machining can be done on any location.

- Requires none or minimal dismantling of large equipment’s.

- Eliminates the need for transport, hence saves on time and costs.

- Overall time and cost reduced, without compromising on quality.

- Better geometrical accuracy than conventional machining in certain cases, as the machining is done in a single setting and assembled condition of the component.

- Dimensional accuracies achievable are as good as conventional machines.

- Inaccuracies and variations developed during fabrication, transportation and erection can be compensated for, by undertaking machining in final assembled condition.

- Latest Laser technology can be used to set up portable machines very accurately.

- Lesser initial investment in capital equipment and floor space.

- Lesser running costs compared to conventional machines.

- Multiple machines can be setup with respect to each other in a single structure, ensuring better geometrical accuracy and saving on overall machining time.