Portable Milling Machine

Pelican has various types of portable milling machines. They all are primarily used for machining fabricated / weld built up / worn out / pre machined surfaces and generate a flat surface. These machines are different from our Circular Flange Facers as these can let the cutter be moved in linear patterns, as different from the circular path of the Flange facer. Complex and irregular shaped surfaces can be machined by controlling the X, Y and Z axis simultaneously. All the machines are transported in parts and can be assembled on site.

The various types of Milling machines are as follows:-

Details

The Gantry Type also known as the X-Y type milling machine is the most versatile, advanced and heavy duty portable milling machine by Pelican. It is very similar to a conventional Plano miller just that it is also portable and in this case the milling spindle travels instead of the job. This machine consists of 2 long travel beds and 2 cross travel beds, both equipped with preloaded linear bearings, as found in the latest and most advanced CNC machines. A twin motor rack and pinion mechanism for long and cross travel along with the help of the linear bearings ensures a smooth and high feed rate, hence increasing the material removal rate tremendously.

The design is rugged and heavy duty, yet portable. The whole machine is transported in parts and assembled on site. The machining capacity can be adjusted as the various beds for long travel and cross travel are interchangeable and made in various lengths. Beds are available in sets of 2 and the lengths are of 1, 2, 3 and 4 metres each. So you can have a gantry size of

2 metres x 4 metres or even 6 metres x 3 metres as required.

A high capacity milling spindle is powered by a heavy duty Hydraulic motor and power pack which enables it to be equipped with a 400 dia milling cutter if need be. Standard milling cutter is a 200 mm dia cutter. High feed rates and large depth of cut helps remove material stock as fast as conventional machines.

Applications

- For machining of large rectangular and square flanges.

- Also used for machining of irregular shaped flanges like in case of gearboxes, mounting pads and gasket faces.

Operations Capable

The standard machine can perform operations such as,

- Face Milling

- Shoulder Milling

- End Milling

- Grooving

- Drilling

Capacity

Milling Cutter dia: - 125 mm to 400 mm dia.

- X axis – 6000 mm

- Y axis – 4000 mm

- Z axis – 1000 mm

Tolerances Achievable

- Surface flatness can be 0.1mm per m. (Depends on the site or job conditions)

- Surface finish is 1.6Ra. (0.8Ra can be achieved by using a grinding attachment)

Technical Parameters

- Feed Mechanism: -

X Axis – Auto (Electrical)

Y Axis – Manual / Auto

Z Axis – Manual / Auto - Milling Spindles Drive: - Electrical / Hydraulic

- Maximum Depth of Cut: - 4mm

- Set-up Time: - 6 to 8 hours

Details

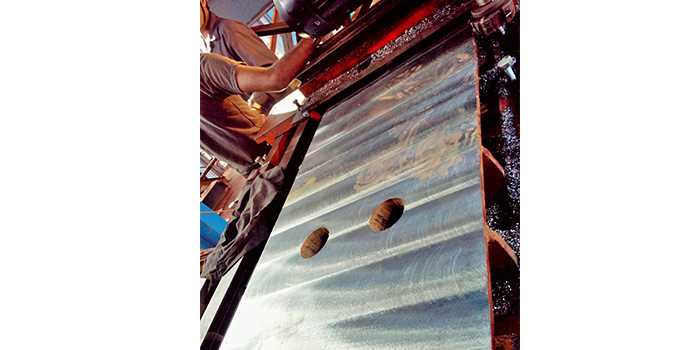

The linear milling machine is generally used for very long milling operations like in case of Dam Gates Slides. In this machine the X axis consists of milling beds in segments of 750 mm as standard and multiple such beds can be joined together to create infinite lengths. The X axis hence is infinite. The standard Y axis and Z axis is 200 mm and 300 mm respectively. As this machine, like every other machine of ours, is custom built; the Y and Z axis feed also can be changed to a certain extent. The standard machine can perform operations such as face milling, shoulder milling, end milling, grooving and drilling. The X axis, long travel, is electrically driven using a feed screw mechanism.

Applications

- In case of very long X Axis machining.

Operations Capable

The standard machine can perform operations such as,

- Face Milling

- Shoulder Milling

- End Milling

- Grooving

- Drilling

Capacity

Milling Cutter dia: - 63 mm to 125 mm dia.

- X axis – infinite

- Y axis – 300 mm

- Z axis – 100 mm

Tolerances Achievable

- Surface flatness can be 0.1mm per m. (Depends on the site or job conditions)

- Surface finish is 1.6Ra. (0.8Ra can be achieved by using a grinding attachment)

Technical Parameters

- Feed Mechanism: -

X Axis – Auto (Electrical)

Y Axis – Manual

Z Axis – Manual - Milling Spindles Drive: - Electrical / Hydraulic

- Maximum Depth of Cut: - 3mm

- Set-up Time: - 4 to 6 hours

Details

The Low Profile milling machine is similar to the Linear Type Milling machine, but is mainly used in locations with confined space. This was developed on a need of the hour basis, for machining the engine mounting bed of a Ship. Due to the confined space a Low Profile (Stub Type) machine was required. The standard machine can perform operations such as face milling, shoulder milling, end milling, grooving and drilling.

Applications

- Used In case of confined space / less working space.

Operations Capable

The standard machine can perform operations such as,

- Face Milling

- Shoulder Milling

- End Milling

- Grooving

- Drilling

Capacity

Milling Cutter dia: - 63 mm to 125 mm dia.

- X axis – infinite

- Y axis – 300 mm

- Z axis – 50 mm

Tolerances Achievable

- Surface flatness can be 0.1mm per m. (Depends on the site or job conditions)

- Surface finish is 1.6Ra. (0.8Ra can be achieved by using a grinding attachment)

Technical Parameters

- Feed Mechanism: -

X Axis – Auto (Electrical)

Y Axis – Manual

Z Axis – Manual - Milling Spindles Drive: - Electrical / Hydraulic

- Maximum Depth of Cut: - 3mm

- Set-up Time: - 4 to 6 hours

Details

This type of milling machine is very compact and light weight. It is designed for groove milling and has smaller X axis length capacity, generally the X axis is 1 to 1.5 metres. It can be mounted in any orientation, be it vertical, horizontal or inclined. It is designed for using endmills as the primary tool with a maximum cutter dia. capacity of 30 mm. It is best suited for onsite machining of gasket grooves in end flanges of tubesheets.

Applications

- In case of groove milling and light use.

Operations Capable

The standard machine can perform operations such as,

- Face Milling

- Shoulder Milling

- End Milling

- Grooving

- Drilling

Capacity

Milling Cutter dia: - 5 mm to 30 mm dia.

- X axis – 1500 mm

- Y axis – 200 mm

- Z axis – 75 mm

Tolerances Achievable

- Surface flatness can be 0.1mm per m. (Depends on the site or job conditions)

- Surface finish is 1.6Ra. (0.8Ra can be achieved by using a grinding attachment)

Technical Parameters

- Feed Mechanism: -

X Axis – Manual

Y Axis – Manual

Z Axis – Manual - Milling Spindles Drive: - Electrical

- Maximum Depth of Cut: - 2mm

- Set-up Time: - 2 to 3 hours